Technology

AquaCon is taking a leading role in creating state of the art land-based facilities for production of fully sustainable Atlantic salmon in the United States. AquaCon’s goal is to change the seafood industry to produce salmon sustainably and environmentally friendly, close to consumers.

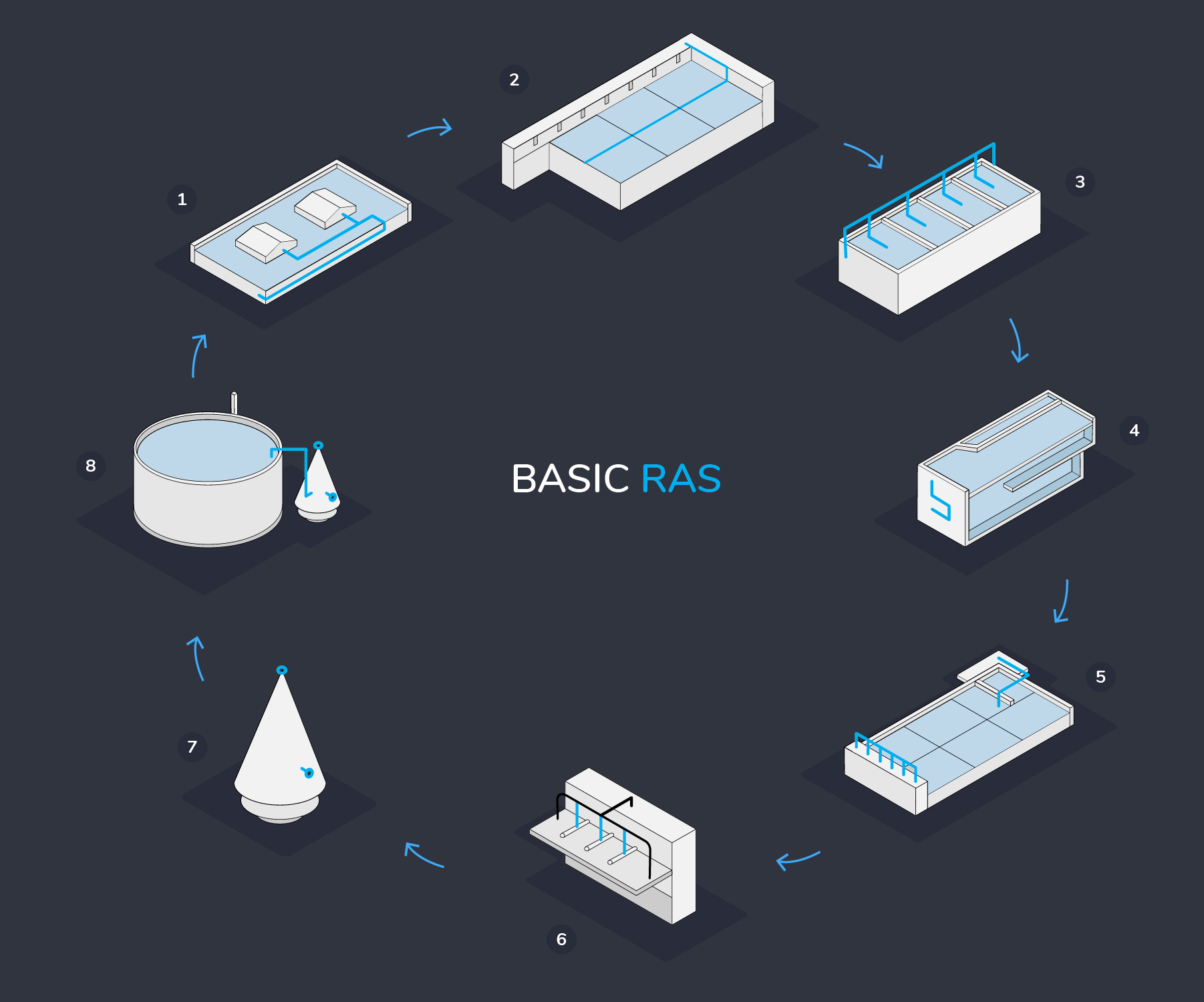

BASIC RAS

Basic RAS is step one in the water treatment that enables us to reuse primary waterflow and uphold the vital water quality parameters and is the core of most commercial RAS systems.

Water exits fish tanks through the outlet system of the plant.

- Mechanical filter: takes out solid from water flow.

- Degassing 1: 50-60% removal of free CO2.

- Biofilter: Primary process is to reduce Total Ammonia Nitrogen (TAN) by using nitrifying bacteria.

- Ozonation: Reduces water turbidity and biological load on system increasing overall water quality, furthermore Off Flavor components are reduced.

- Degassing 2: 50-60% removal of free CO2.

- Main pumps: Ensure an efficient water flow only lifting the water needed.

- Oxygenation: Is done by letting the water flow enter oxygen cones and injecting oxygen.

- Fish tanks: The water returns to the fish with optimal water quality ensuring a prosperous fish growth.

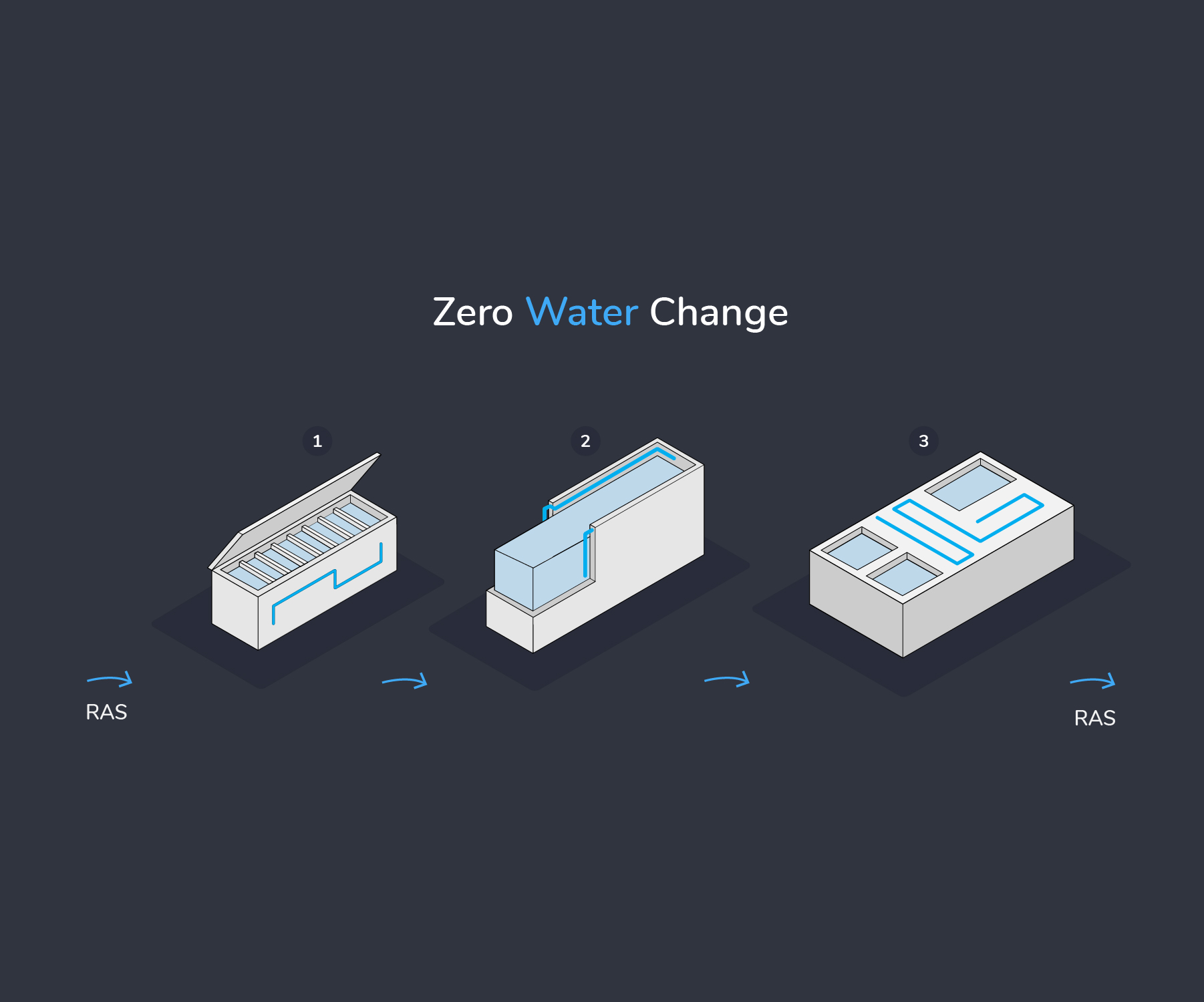

Zero Water Change

Zero Water Change goes a step further in reusing water by solid extraction, denitrification and phosphorus removal.

- Plate separator: Solids extracted by mechanical filters are concentrated. Concentrate goes to WWTP.

- De-nitrification: Reject water from Plate separator goes to this biofilter which transforms Nitrate (NO3) to Free Nitrogen gas (N2) that evaporates back to the atmosphere.

- De-phosphorus: Treated water from De-nitrification goes to De-phosphorus system which by addition of Iron chloride precipitates Phosphorus in a concentrated form that goes to WWTP.

Waster water Treatment

WWTP is the final step in water treatment and converting solid waste to bioenergy and soil enrichment product.

- Mechanical filter: Various dirty waste streams from Basic RAS and ZWC are separated by mechanical filters into sludge fraction and water fraction (reject water).

- Biogas: Sludge waste with ca 6% dry matter is going to Anaerobic Digester (AD/Biogas reactor) which converts it to fuel-grade bio-methane and thereby reducing solids by more than 60%.

- Dryer: Solids are dried with waste heat to 94% dry soil enrichment product with high Phosphorus content (Ca. 100 grams/kg feed usage).

- Biofilter: Reject water post Biogas reactor with high levels of Nitrogen (NH3/4) goes to a biofilter that converts the Nitrogen to Free Nitrogen gas (N2) that evaporates back to the atmosphere.

- Ozonation: Disinfection by Ozonation followed by aeration to remove CO2 and Off Flavors.

AKVA Group

The AKVA Group is a leading technology and service partner for aquaculture technology, with more than 30 years of experience. Their team of world leading experts are renowned for designing sustainable recirculation and land-based fish farming systems that are second to none, and provide optimal water quality conditions needed in land based fish farming. AKVA Group Land Based delivers complete fish farming solutions from pre-project to completed installations, commissioning, training and for follow-up and maintenance, and will be fully involved in the establishment of our land-based facilities.

Agreement with Benchmark Genetics

Agreement in place with Benchmark Genetics securing salmon eggs for the first 50,000 tonnes of production. Benchmark Genetics is an industry recognized innovator in breeding and genetics for aquaculture, supplying its brands globally to more than 70 countries.